New Trends in Processing Systems

New Trends in Processing Systems

New Trends in Industrial Automation and Machining Systems

Industrial automation and machining systems play a critical role in increasing speed, efficiency, and safety in modern manufacturing processes.

Today, companies focus on optimizing production lines not only through manual processes but also by utilizing smart equipment and automation technologies.

Smart devices equipped with sensors and data analytics allow real-time monitoring of production processes, early detection of potential errors, and improved operational efficiency.

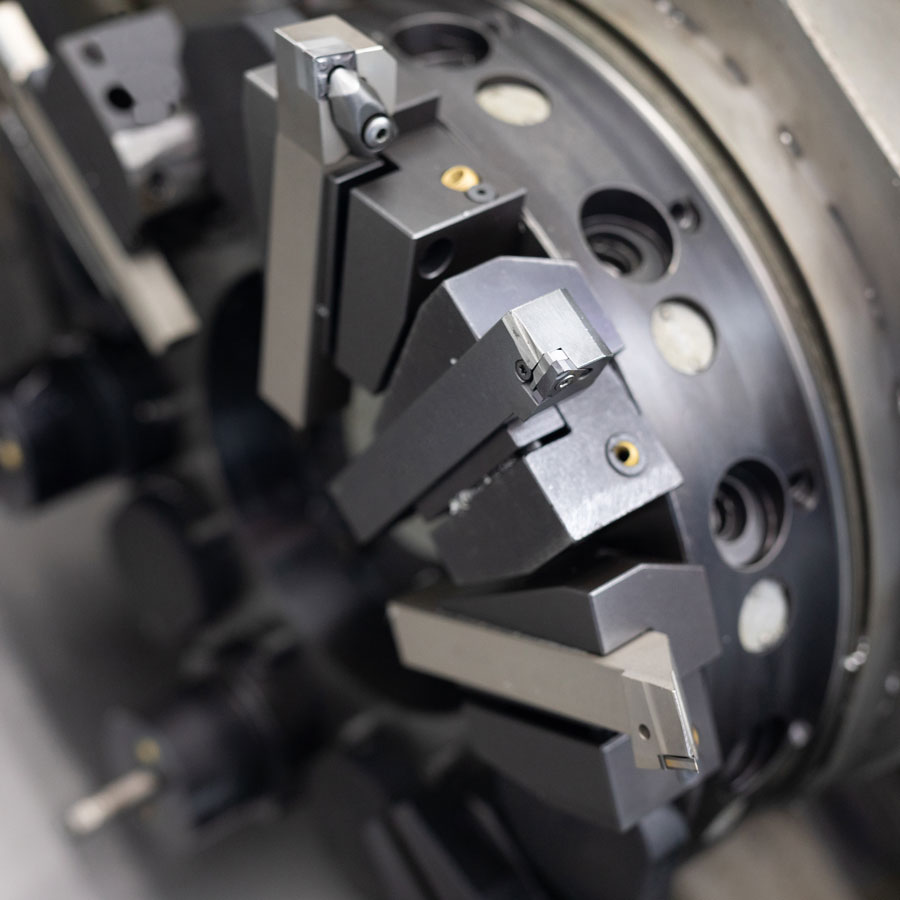

Robotic systems and automated fixture solutions enable complex workpieces to be processed quickly and accurately, reducing production time and minimizing human error.

Additionally, data-driven manufacturing, or "Smart Manufacturing," enables the optimization of production processes through data analysis.

This approach increases efficiency while also optimizing energy and raw material usage.

Integration of Industry 4.0 and Internet of Things (IoT) technologies connects all devices on the production line, allowing centralized monitoring and analysis.

Production line issues can be detected instantly, and interventions can be made in real time.

These advancements not only increase production speed but also ensure the maintenance of quality standards and the creation of sustainable manufacturing processes.

At Vento Global, we closely follow the latest automation and machining technologies to help our customers achieve maximum efficiency and quality in their production processes.

We provide smart, innovative, and industry-specific solutions that enhance manufacturing performance and support sustainable growth.